Door: Luuk Timmermans, Practice lead Field Service bij Appsolutely en Coen Jeukens, VP Global customer transformation bij Servicemax.

18 november 2021 stond ons live evenement over Digitale transformatie in de field service operatie gepland. Door corona is het helaas niet doorgegaan. Doel van het evenement was om te inspireren met klantvoorbeelden uit de praktijk en kennis van experts uit het werkveld. Om de mooie verhalen die waren voorbereid toch met jullie te kunnen delen hebben we deze, de afgelopen twee maanden, met jullie gedeeld in de webinars met Guidion en Reinier Haga Medisch Diagnostisch Centrum. Vandaag is ook het verhaal van ServiceMax gepubliceerd in deze video. Doel van dit blog is om, over de drie verhalen over digitale transformatie heen, te delen wat ons is opgevallen.

Luuk Timmermans

Terugkijkend op de webinars en video zijn er een aantal dingen die mij zijn opgevallen en die ik interessant vind om te benoemen.

Om te beginnen herken ik mij helemaal in de constatering in de video van Coen dat klanten tegenwoordig veeleisender en mondiger zijn. Er wordt een pro-actieve houding verwacht van dienstverleners. Dit is het geval in de context van complexe assets die worden verkocht en assets die als een dienst worden verstrekt aan de klant. Dan wordt bijvoorbeeld verwacht dat de dienstverlening proactief is en assets voorspelbaar presteren. Maar dit geldt ook als er sprake is van meer transactionele diensten en de klant verwacht dat er bijvoorbeeld proactief gecommuniceerd wordt over de dienstverlening en eventuele afwijkingen op gemaakte afspraken. Deze ontwikkelingen in de verwachtingen liggen ten grondslag aan de noodzaak om te digitaliseren voor organisaties als Guidion en Reinier Haga Medisch Diagnostisch Centrum.

Waarde & Zichtbaarheid

Er zijn natuurlijk meer waardedrijvers zoals bijvoorbeeld kostenreductie en omzetstijging. Uiteindelijk is, zoals Coen aangeeft in zijn video, zichtbaarheid en controle over producten, medewerkers en producten de sleutel om op elk van deze onderdelen succesvol te kunnen zijn. RHMDC in het webinar en Nilfisk laten zien dat aan de voorkant deze relatie niet altijd aantoonbaar en kwantificeerbaar is. En dat starten met digitale transformatie uit geloof in de noodzaak zonder harde onderbouwing zich terugbetaalt in resultaten die aan de voorkant verwacht waren, maar ook met waardevolle resultaten die niet verwacht waren. Zo biedt het inzicht in de staat van de assets van RHMDC commerciële kansen die niet waren voorzien.

Ben je geïnteresseerd in meer klantvoorbeelden waarin inzicht randvoorwaardelijk vanuit commercieel perspectief is? Kijk dan eens naar deze klantcase van Schneider Electric.

Mensgerichte aanpak & duurzaam resultaat

Niet alleen klanten verwachten meer, maar medewerkers ook. De aanpak van Guidion en RHMDC hebben overeenkomsten in de mensgerichte aanpak. Beiden laten zien dat het zorgvuldig betrekken en meenemen van alle stakeholders randvoorwaarde is voor succes. Bij Guidion doen ze dat door bij de inrichting van de digitale oplossingen niet alleen te kijken naar de beleving van de klant in een ‘klantreis’ maar ook met de medewerker vanuit een ‘medewerkerreis’. Ook bij RHMDC zaten de gebruikers zelf aan het stuur om aan te geven hoe de inrichting van de oplossing hun werk leuker en makkelijker kan maken. Uit beide voorbeelden spreekt de overtuiging dat duurzaam resultaat voor het bedrijf voortkomt uit een mensgerichte aanpak.

Coen Jeukens

Wat overduidelijk opvalt in alle serviceverhalen, is dat het mensenwerk is. Zoveel mensen, zoveel wensen. Dat uit zich enerzijds in een stroming om processen te willen standaardiseren. Om daarmee mate van controle en efficiency bereiken. Anderzijds is er een stroming van situationeel maatwerk. Daarmee inhakend op een gevoel van autonomie en eigenheid. Dit werd mooi verwoord door Guidion. Zij werken met verschillende klantprofielen waarbij de workflow per profiel kan verschillen.

Klant 360, Workforce 360 en Asset 360

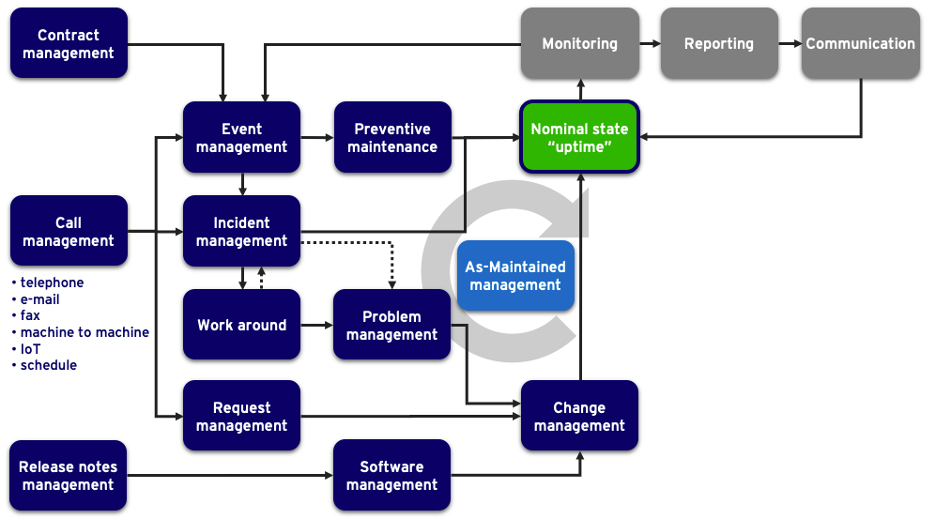

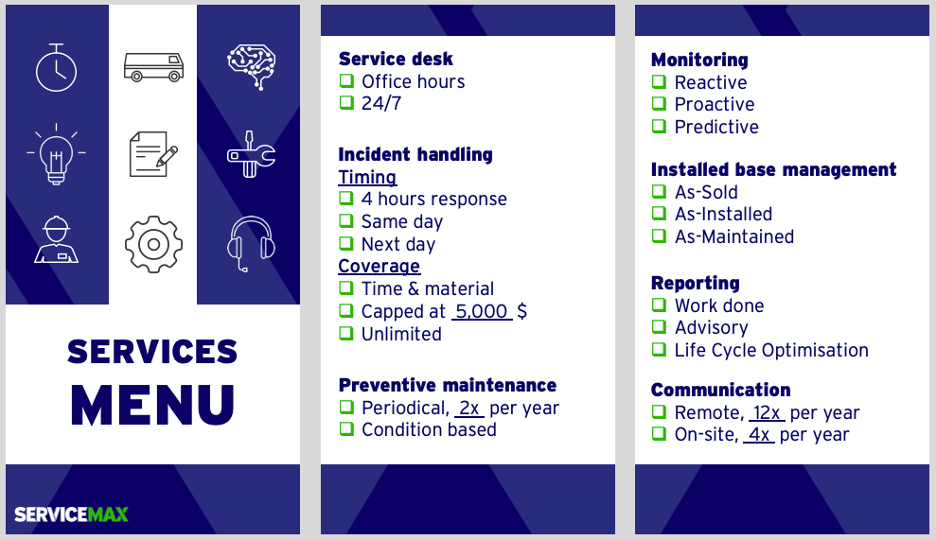

ServiceMax heeft in 2019 een onderzoek laten uitvoeren door Forrester om uit te zoeken wat de bouwstenen zijn van een serviceorganisatie. Naast de overduidelijke Klant 360 komen daar de Workforce en de Asset 360 bij.

In de verhalen van Guidion en RHMDC worden mooie voorbeelden gegeven van Workforce 360. Het maakt namelijk nogal een verschil of je workforce interne mensen, contractors of ZPP-ers zijn. Dit uit zich in de mate van controle, zichtbaarheid en inzetbaarheid die je over je workforce hebt. En vergeet ook niet de kwaliteit, loyaliteit en mate waarin je workforce je visitekaartje is.

In de video van ServiceMax is veel aandacht gegeven aan de Asset 360. De gedachte erachter: je moet wel weten welke producten er bij een klant staan, in welke staat die zich bevinden en hoe ze worden gebruikt om doelgericht service te kunnen verlenen. Heb je een 360 graden zicht op de asset, dan stelt die zichtbaarheid je in staat om zowel efficiënt te zijn langs de kosten-as, als wel effectief te zijn langs de commerciële-as.

Customer Intimacy

Wat mij al 29 jaar grijpt in het servicevak is de mengelmoes van harde cijfers zoals kostenreductie en omzetgroei en zachte indicatoren als klanttevredenheid en beleving. Evenzo de spanning tussen controle en autonomie. In alle drie de presentaties zien wij dit terugkomen. Toen Youp van ’t Hek in 2010 van leer trok vanwege een service-akkefietje over het mobieltje van zijn zoon, bleek dat iedereen een mening en verwachting had over wat service zou moeten zijn. In dat jaar ben ik Youp op een congres tegengekomen en heb aan hem gevraagd: “Je had overduidelijk een verwachting, was die verwachting ook in lijn met het serviceniveau waarvoor je had betaald?”. En daar zit hem nu vaak de kneep. Kan je die verwachting managen? En welke tools/processen heb je daarvoor nodig? In 2010 was Youp heel mondig en zocht hij meerdere kanalen om zijn verhaal te vertellen. Anno 2022 kunnen serviceorganisaties beschikken over tools en processen om contextuele service te verlenen… en om Youp van repliek te voorzien.

Met het delen van bovenstaande observaties en verbanden tussen de webinars van Guidion, Reinier Haga MDC en de video van ServiceMax hebben we een poging gedaan een relatie te leggen en de rode draad te schetsen tussen de verschillende onderdelen. Net zoals dat normaal in je eigen gedachten plaats zou hebben gevonden als je het live evenement in zijn oorspronkelijke vorm had kunnen bijwonen. We hopen dat daarmee dit blog een waardevolle samenvatting geeft van hetgeen aan de orde is geweest en zien er naar uit komend jaar een vergelijkbaar evenement weer live te kunnen organiseren.

Deze blog is als origineel gepost op de website van AppSolutely.