In my previous blog, I wrote about the blindfold-challenge; sending a service technician into the field with impaired visibility on an installed product, scarce access to knowledge, and poor spare parts support. The challenge hit a nerve with many based on our numerous responses. This challenge proved that getting the job done is more than having a customer service department and a sophisticated scheduling tool. You need insights into the installed product such as how it was engineered, how it was installed, and how it is maintained and used.

In this blog, I will go over using engineering information such as asset-centricity, asset lifecycle, and real-life information for efficient service delivery.

Asset Centricity

Can you imagine how frustrating it is for a technician, to be sent on a job, showing up and feeling the pressure to perform a miracle in the absence of essential product information? This is the reality of the traditional reactive-break-fix model. Not only does this model affect the technician, but it also aggravates customers, service managers, and CFOs.

Customers expect their products to work, and if they don’t, they insist on an instant and first-time fix. Service managers care about utilization and cost, only to get inefficiency caused by technicians scrouging for information and parts. CFOs want predictable earnings, only to get margin contribution at a risk due to unplanned service costs.

The alternative to the above blockers is embracing the concept of asset centricity. Instead of hopping from one isolated reactive incident to the next, we want to position the installed product at the core of the service delivery model. With asset centricity, we collect and connect the data from all the interactions we have with the product over its lifecycle. As a result, we can deliver proactive, predictive, and prescriptive services. Instead of fixing what breaks, we’ll know what works.

Wider perspective

With an asset centric approach, the technician will have a lifecycle view of a product. Meaning, having visibility of all historical and upcoming service events for those products. These insights put the current job in a wider perspective. The bigger picture allows the technician to make better decisions and deliver service faster, better, and cheaper. This will allow the technician to know what was installed and how the product is being maintained and used. They will also know what engineering changes and upgrades are available for that product.

Having a wider perspective on the As-Installed and As-Maintained is already a tremendous help to the technician, still an important piece of information is missing; the plan, the reference.

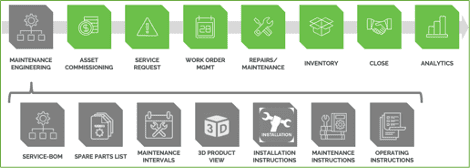

When the product was designed, the engineers had a specific use case in mind. Based on that use case, the maintenance engineering function defines the service-BoM, the spare parts list, maintenance intervals, and a whole array of reference documents. This maintenance engineering data will enable the service delivery organization to plan the work and get the job done. When putting this information in the hands of the technician, the technician would both be informed and empowered for success, removing the metaphorical blindfold.

Plan versus Actual Data

When a product is ‘in the field’ it generates data on how it performs and what maintenance interventions it incurs. This is called “actual” data. The reference data from maintenance engineering serves as “plan” data. When you set up your service delivery organization to combine both sets of data, you have created a powerful tool to manage the service lifecycle of your installed base. At PTC we call this service lifecycle management (SLM).

“Plan” data will help you to prepare, be effective, and be efficient. When the actual data equals plan data, you’re on course. When they don’t equal each other, you trigger a mitigating action. There are a few reasons this may occur. It could be the customers are using the product differently than the intended use case or not all prescribed maintenance procedures were followed. It also could be the engineers had a different perception of real-life data. Whatever the cause, managing the data is at the core of successful service lifecycle management.

Efficient service delivery

Let’s give some examples of successful service lifecycle management through the lens of today’s three service delivery challenges.

- Technician shortage: Almost every service organization is in search of technicians. Getting the job done is generally treated as a capacity and utilization problem. However, when organizations remove the blindfold and empower technicians it not only leads to achieving efficiency but also creates a more fulfilling job leading to more applicants.

- Identifying the right part: When we ask technicians about their main pains, the identification of spare parts is in the top 3. In selecting a field service management (FSM) tool – optimizing for the labor component – is often the primary focus, but we fail to realize that parts cost is 40-60% of service cost. If you have a better record of the installed and maintained bill-of-material, your identification process would be more effective leading to a faster, better, and more efficient fix.

- Knowing what must be done: Modern-day products are getting more and more complex. Good to know that engineering has defined instructions, dos, and don’ts to sustain the outcome of a product. When we use this data as a reference when we install and maintain an instance of a product, we can provide the technician with contextual information needed to perform the tasks without being blindfolded.

If you would like to hear more context and interact with experts from PTC, please join us in person at the High Tech Campus in Eindhoven on March 15th or tune in to the PTC Talks on April 12th.

This article is published on Field Service Digital.