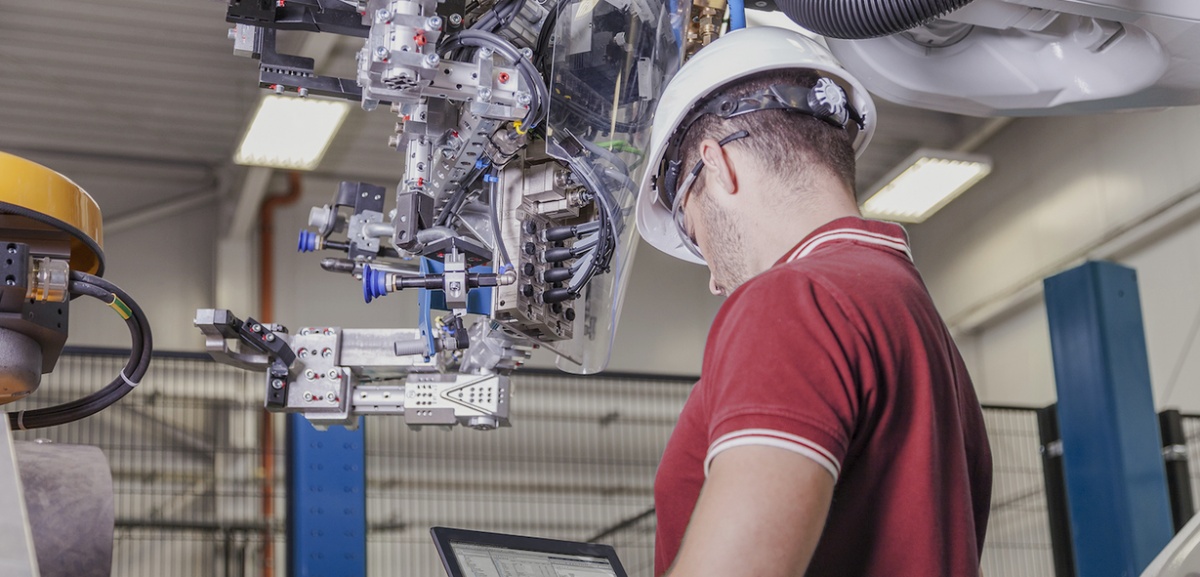

Over the last few years, the topic of technician/talent shortage has been getting more and more traction at service industry events. Analyst firms Forrester, IDC, TSIA, Aberdeen and The Service Council are too in unison about the technician gap. And not only are service organizations struggling to find enough candidates, but they are also struggling to find ones with the right skills—especially as the nature of service jobs evolves beyond simply fixing a piece of equipment. Candidates must also be able to:

- Adapt to and learn about new technology tools attached to service work

- Learn about new service procedures tied to more complex service assets

- Work in a group or team environment

- Be able to work and engage with the customer

Once you overcome these obstacles and hire new technicians, how can you quickly get them onboarded and delivering value? In a 2017 survey from the Aeronautical Repair Station Association, the average time for a technician to become fully profitable lies between 9 and 24 months. This represents an onboarding investment of between $132,750 and $354,000. Per industry, the values may differ, but the onboarding time is pretty much consistent across organizations. As you can see, being able to improve new technician time to value can make a big difference on the bottom line.

The changing demographics of the workforce adds another layer of complexity. For Millennials, on the job learning is done a bit differently than previous generations. Rather than relying on cumbersome textbooks, they can search the web for the exact info they need or ask their peers. This has implications on the tools you provide to millennials. Having digital business tools with a consumer look and feel and ease of use can go a long way in training, as well as attracting younger talent. Modern service execution tools and millennial learning habits may be your ticket to faster time to value.

Five Ways to Improve New Technician Time to Value

1. Make jobs simpler

Different service jobs have different characteristics and skill requirements. Through slicing and dicing of the jobs and smart dispatching, you can assign simpler tasks to junior resources. Based on their track record and development they can move up the ladder.

2. Facilitate access to information

As much information you want to provide to a technician when dispatching the job, the reality onsite may be different. Proving access to relevant and adjacent information in an on-demand mode will allow your technician to become self-sufficient.

3. Deploy contingent workflows

An installation, break-fix, inspection and preventive maintenance job probably will have different workflows. A workflow may even differ per customer. Instead of requiring your technicians to learn and remember all variants, use a field service management tool to assist and even prescribe workflows.

4. Assist humans with machine learning

Throughout the lifecycle of a product, the product itself and all human interactions generate a lot of data. Mining that data and creating insights allows humans to make better decisions. Simple tasks can be automated creating more meaningful work for technicians.

5. Interweave social interaction into the job

Even when automating many aspects of service, it is the people-component that cements it all together. Call it assisted service with a human touch. Using voice-calls or messaging is an integral part of the job. Interweaving those social interactions into the job creates context and makes the communication more efficient. Try to facilitate connected conversations and conversational workflow for your employees, and make sure it is on an enterprise-grade platform to protect your intellectual property.

This article is published in ServiceMax Field Service Digital on February 11th, 2020